We are specialists in PCB assembly, including:

- SMT (Surface Mount Technology) assembly

- THT (Through-Hole Technology) assembly

- Mechanical assembly

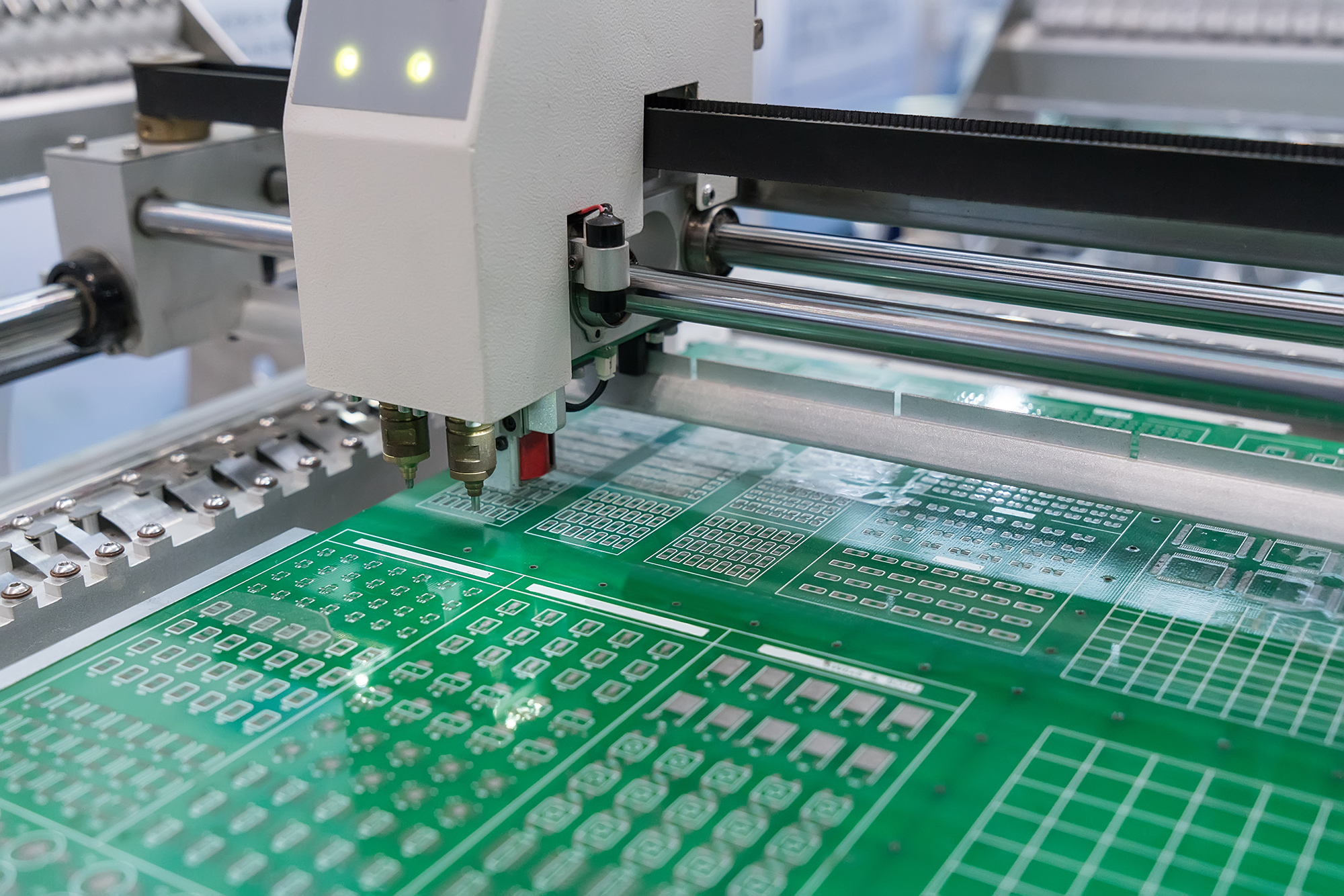

SMT assembly

We have 5 full lines for SMT components assembly. These differentiated lines provide a high manufacturing versatility and allow us to manufacture any series – short or high volume.

Versatility, scalability, flexibility… these topics are in the DNA of Tef. We can set any changes in quickly and effectively, reorganize us when it’s necessary and optimize our resources to get the most operational production process.

Each SMT assembly line includes serigraphy, pick & place and ovens, with all the required conveyors, carriers and unloaders to achieve the best operation of each line.

Line 1:

- AT Screen Printing: Solder paste printer Mod. AT

- SPI 3D: Pemsaturn-4MP – Saturn Inline Solder Paste Inspection

- Pick and Place 471: High-speed flexible mounter SM471

- Pick and Place 482: Multi-functional placer SM482 Plus

- 11-Way Oven: Lead-free reflow oven with 10 heating zones model MSTR-1000

- AOI 3D: Eagle 8800HSL

Line 2:

- AT Screen Printing: Solder paste printer Mod. AT

- SPI 3D: Pemsaturn-4MP – Saturn Inline Solder Paste Inspection

- Pick and Place 471: High-speed flexible mounter SM471

- Pick and Place 482: Multi-functional placer SM482 Plus

- 11-Way Oven: Lead-free reflow oven with 10 heating zones model MSTR-1000

- AOI 3D: Eagle 8800HSL

Line 3:

- AT Screen Printing: Solder paste printer Mod. AT

- SPI 3D: Pemsaturn-4MP – Saturn Inline Solder Paste Inspection

- Pick and Place 471: High-speed flexible mounter SM471

- Pick and Place 482: Multi-functional placer SM482 Plus

- 11-Way Oven: Lead-free reflow oven with 10 heating zones model MSTR-1000

- AOI 3D: Eagle 8800HSL

Line 4:

- AT Screen Printing: Solder paste printer Mod. AT

- SPI 3D: Pemsaturn-4MP – Saturn Inline Solder Paste Inspection

- Pick and Place 471: High-speed flexible mounter SM471

- Pick and Place 482: Multi-functional placer SM482 Plus

- 11-Way Oven: Lead-free reflow oven with 10 heating zones model MSTR-1000

- AOI 3D: Eagle 8800HSL

Line 5:

- AT Screen Printing: Solder paste printer Mod. AT

- SPI 3D: Pemsaturn-4MP – Saturn Inline Solder Paste Inspection

- Pick and Place 471: High-speed flexible mounter SM471

- Pick and Place 482: Multi-functional placer SM482 Plus

- 11-Way Oven: Lead-free reflow oven with 10 heating zones model MSTR-1000

- AOI 3D: Eagle 8800HSL

THT assembly

THT –or conventional assembly– is performed manually, so it allows any component and any amount to be assembled. Once the components have been placed on the PCB, we can implement the welding with one of these systems:

- flow machines

- manually

PCB are finished according to the specifications required by the customer.

Mechanical assembly

PCB or equipment finishing according to specific specifications, packaging and shipping preparations are also part of our activity. Our traceability system allows us to perform a complete follow-up of the process, since the product is finished until it arrives at the customer premises.

We have a long experience with multiple formats targeted to any manufacturing industry. We assemble and ship PCBs for professional audio systems, ATMs, instrumentation, machinery parts, medical equipment, signage and many other devices… We know how to do it.